All-Italian Quality Sistem

SBE In Numeri

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

3DX Deformable Die System

For nearly 30 years, deformable ring systems have helped blow moulding machine manufacturers save material, achieve critical wall thicknesses, and meet stringent requirements for automotive parts and UN/DOT certified containers.

Our products

S.B.E. has always been using only the best alloys and has given each product to long-term quality tests to guarantee all our customers the best performance and longer life of the devices.

Parison programmer

Retrofit

Spare parts

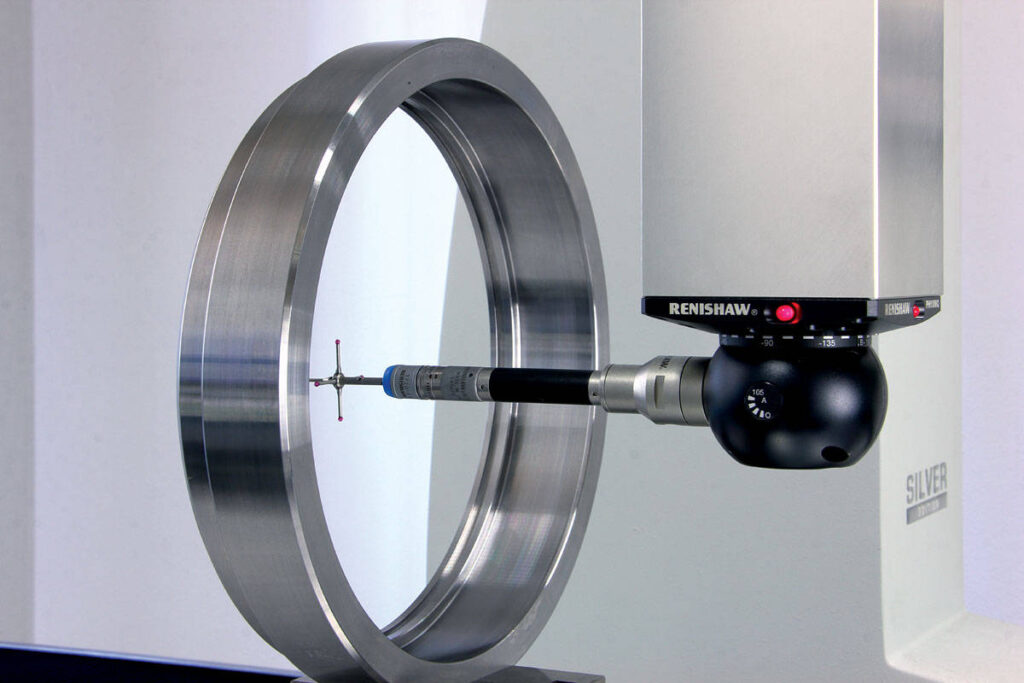

Quality of S.B.E.

S.B.E. is known and appreciated all over the world for great attention to the quality of materials, services offered and diligence at every stage of production, from design to assembly. Thanks to many years of experience and the production of precise mechanical components with a wide range of applications in the field of blow moulding containers

Our services

S.B.E. also offers a range of highly qualified and specialized services to support all companies operating in the plastics blowing sector.

Revamping

On-site assistance

Engineering and consulting

Documenti

In questa sezione è possibile consultare e scaricare la documentazione importante come cataloghi, manuali, brevetti e altre informazioni utili

Cataloghi

Manuali

Brevetti

Dicono di noi

Lorem ipsum dolor sit amet, consectetur adipiscing elit.